6 ways you can benefit from a case erector

Whether you’re a manufacturer, distributor or online retailer, time is money. That’s why looking for ways to optimise your production line and how you pack your products can be critical.

So, have you ever considered using a case erector? Also called a carton erector or auto carton erector, these advanced machines can improve how you deal with your cardboard boxes.

This article will explain what a case erector is. It will also discuss the various types of case erecting machines. Additionally, it will explain the benefits of using one in your production line.

- 1.

- 2.

- 3.

- 4.

What is a case erector?

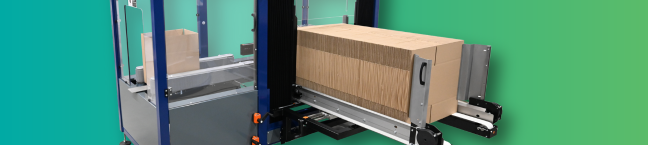

A case erector is a type of packaging machinery designed to automatically erect and seal corrugated cardboard boxes. They can simplify the packing process and significantly improve productivity, especially when used alongside other packaging automation.

Also known as carton erectors, these machines efficiently erect various box sizes and styles (depending on the machine selected). They offer a versatile solution for businesses with diverse packaging needs.

Do not confuse case erectors with case sealers, machines that seal boxes with either packing tape or glue.

Types of case erectors

There are several different types of case and carton erectors available on the market. We separate them into three broad categories:

Semi-automatic case erectors

Semi-automatic carton erectors will automate part of your box erection. They require some manual intervention, typically in loading flat boxes into the system. Once loaded, the case erector automates the process of erecting and sealing the boxes.

Often, semi-automatic carton erectors can be a good first step for box automation. They can sometimes be used as a stand-alone machine, to help with easy packing, or paired with a case sealer.

Automatic case erectors

Fully automated, this type of carton erector performs the entire box assembly process without the need for manual input. Automated carton erectors often offer case sealers that can use glue or tape. They are highly efficient, reducing labour requirements and increasing overall productivity.

This type of erector is good for higher-demand environments. You can modify many high-spec automated carton erectors to suit operational requirements too.

See one of the models Macfarlane can supply in action

Random case erectors

Random carton erectors handle a variety of box sizes without needing adjustments. This type of erector is ideal for businesses dealing with a diverse range of products.

Both standard carton erectors and random carton erectors work with pre-formed corrugated cardboard boxes. For example, a FEFCO 0201 style box. Random carton erectors can erect different size and shape boxes.

Right-size carton systems

In addition to the erectors mentioned, it’s also worth noting right-size carton systems. While they are technically not case erectors, they are a type of packaging automation associated with boxes.

A right-size carton system essentially builds the right-size box for a product. This can be from a continuous fanfold of corrugated material or tray style boxes that are reduced in height before a lid is glued on. They are also known as void-reduction systems, as they minimise the amount of empty space in the finished pack.

So, which type of case erector is best?

There are many different brands of case erectors on the market. The type of case erector that will be right for you will depend on several factors, such as what you’re packing and shipping, product weight, how the package will be stored and shipped, as well as your production environment.

Consulting with a packaging automation expert before investing in machinery like this is always worth it. It can help you choose a case erector that will deliver what you need for your business.

Depending on your business maturity, you might be ready for a case erector now. Alternatively, you might consider an interim solution like a box erecting frame before you progress to machinery. This video highlights signs you’re ready for packaging automation.

6 ways you can benefit from a case erector

Now you know what a case erector is and the different types available, how can a case erector benefit you? Here are six ways your business can benefit from a case erector:

1. Speed and Efficiency

Automatic carton erectors drastically reduce the time and effort required for box assembly. Some models offer a 233% productivity increase compared to manual processes. Case erecting machines erect and seal boxes at a much faster rate than manual methods. This significantly boosts overall productivity.

2. Precision and Consistency

Manual processes come with the risk of human error. Case erectors ensure precise and consistent results when assembling cardboard boxes. This leads to improved product protection during transit and enhances the overall quality of your packaging. Plus, if you’re palletising your product, case erectors can provide square cases every time, which means they’re easier to stack as well.

3. Environmental Impact

The precision and consistency associated with a case erector can also reduce your environmental impact. Erectors eliminate waste that human error can produce, resulting in less waste to recycle or dispose of.

In addition, square cases every time can help manage your parcel cubage minimising CO2 emissions during transport. Another eco-friendly benefit is reducing damages in transit. This is because it cuts out the potential emissions (and cost) associated with reverse logistics.

4. Enhanced Workplace Safety

Many manual processes, such as box assembly, packing and sealing, can lead to repetitive strain injuries and staff fatigue. By automating the box erecting process, case erectors contribute to a safer working environment by minimising physical strain on your team.

5. Improved Brand Image

Consistently well-packaged products contribute to a positive brand image. Using a case erector ensures that your boxes are neatly and professionally assembled – reflecting your brand image. This can be particularly important in the online retail sector, where packaging is often the first physical touchpoint with a business!

6. Cost Savings

When you think about investing in a case erector (or any packaging machinery) cost savings might not be the first thing that comes to mind! However, while the initial investment in a case erector may seem substantial, the long-term cost savings are significant.

Due to the efficiencies offered by a case erector, you can reduce labour costs, including the need for temporary labour during peak times. Plus, you can often reduce the amount of packing material you’re using, which results in further savings.

In addition, your production throughout put can increase significantly, helping you keep up as your business grows. Ultimately, you can enjoy a more cost-effective packing process.

Summary

Introducing a case erector into your packaging line is an intelligent move that can pay dividends. Opting for automation will help you move towards efficiency, cost savings, and improved packing quality. If you leverage packaging automation, you will be better positioned to thrive in the competitive landscape and future-proof your packing operation.

So, if you need help with a case erector (or any packaging machinery), please speak with one of our experts today.