Case Study: Industrial

Customer: A leading developer of industrial and commercial inkjet, thermal transfer, digital and laser printing products

Application

With a view to improving the sustainability of their packaging, our customer requested an evaluation of materials that could have a lower environmental impact.

We were tasked to find 3 new concepts that would best suit their latest manufacturing project and deliver high levels of protection.

Solution

Macfarlane undertook a programme of analysis of 8 different materials, and conducted compression (taking into account climatic allowance), vibration and shock/impact tests on each.

For comparison purposes, the materials test included bamboo, EPS, EPP, corrugate, fibre pulp, mushroom and plastic.

Each material was rated on it’s test performance results as well as it’s benefits and disadvantages—factors like availability, storage space required and manufacturing MOQs.

Results

We delivered a full report of material analysis to the customer, enabling them to make an informed choice for their packaging materials, supporting their sustainability objectives and shaping their future.

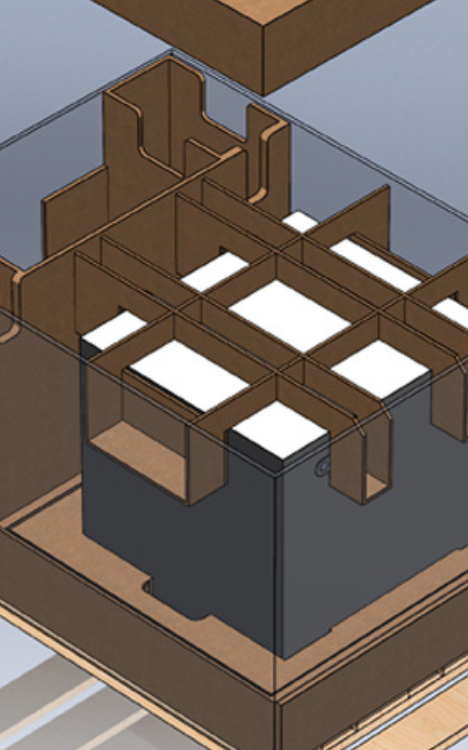

The final solution consisted of a corrugated board base with top dividers to replace existing polyethylene foam fittings.

The pack was extremely lightweight, easy to recycle, had excellent structural strength and delivered material cost savings of 12%