Sustainable packaging swaps for manufacturers

As the public is becoming increasingly aware of environmental issues, manufacturers are under growing pressure to adopt more sustainable practices. A …

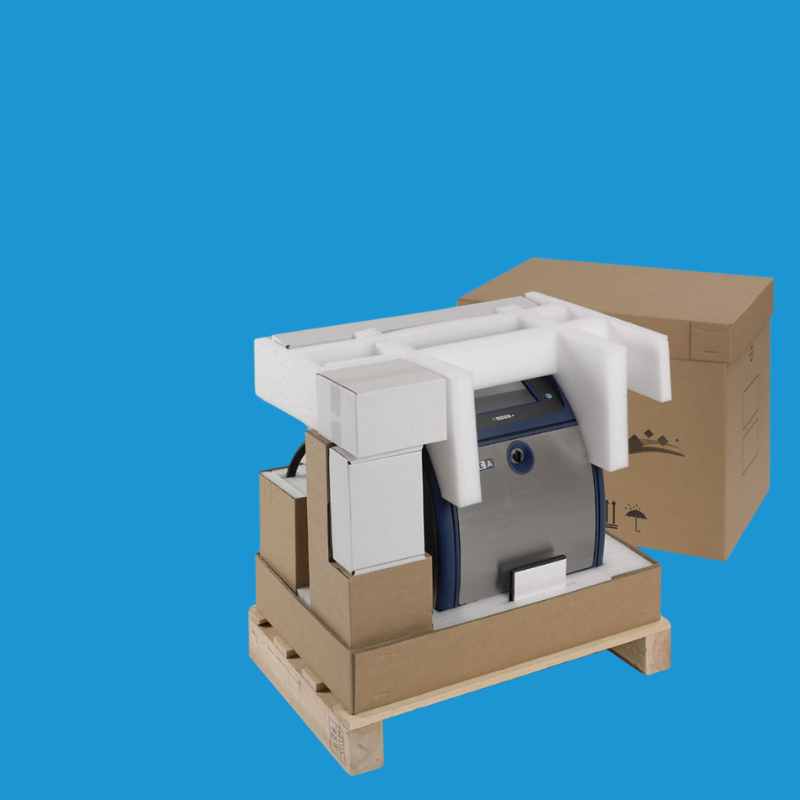

Macfarlane Packaging’s specialist manufacturing brands can design and manufacture protective packaging for your high-value and fragile items. Our design expertise, combined with our materials knowledge and production capabilities, enables us to:

Does your current packaging guard against all forms of logistics hazards, including extreme climate and environmental conditions? Our solutions will safeguard your goods.

The correct packaging solution can reduce material usage, eliminate waste, improve sustainability, and free up labour and storage space for more productive use.

Developing a new product? We work with your design team to ensure that your products are perfectly packaged to make your launch and shipment programme delay and trouble-free.

All our industrial packaging solutions are made to order at one of our UK manufacturing sites. Below are examples of the types of specialist packaging products we can prove. From heavy-duty corrugated through to flight cases, timber crates and even conductive packaging.

Heavy duty corrugated cardboard, including Tri-Mite, can be made into bespoke size solutions that helps ensure space savings, lower transit costs and emissions.

It can be finished with handles, specialist coatings and printing.

When combined with materials like foam and timber supports to make composite packaging, you can achieve the ultimate protection for your products.

Timber packaging can be custom-made to fit specific components. It is ideal for shipping large objects, such as panels, assemblies and even engine blocks.

We can make timber cases and boxes from many different types of wood, including plywood, OSB (Oriented Strand Board), particle board, MDF (Medium Density Fibreboard) and hardboard. Plus, we can manufacture solutions that are IPSM15 compliant.

Protective cases are great for storing, transporting and organising various tools and equipment.

Options include waterproof cases, such as Peli™ cases, lightweight carry cases, roto-moulded cases, aluminium cases, plastic carry cases and popular flight cases. Sample / sales demo cases as well as custom built solutions are also available.

All protective cases can be made with custom inserts.

Our specialist foam packaging can be made from a range of Plastazote®, Ethafoam and Stratocell foam.

Options include foam inserts, end caps and foam dunnage, as well as antistatic foam.

We can convert foam to your specific requirements, giving you ideal protection for fraile and high value goods.

Strong and durable Correx® corrugated plastic packaging can be made into tote boxes and containers, picking bins, postal boxes, dividers and inserts as well as handling trays.

Available various grades and colours, Correx® is a returnable, reusable, water-resistant and inert industrial packaging option. It’s ideal for storage, shipping and closed loop systems.

Conductive packaging conducts electric charges away from the static-sensitive products.

Options available include Corstat cardboard; plastic-based solutions, such as Corriplast, moulded plastics and ESD-safe foams.

Ideal for businesses in electronics, automotive, telecoms, aerospace and computing.

Our specialist manufacturing division can provide a wide range of containers including satellite and sensitive equipment containers, large-scale containers and even DELTA® containers.

Design and bespoke fabrication service scan provide the containers you need across a wide range of sizes and specs.

Looking for a rack case? We can provide performance 19″ rack cases for your valuable electronic equipment and systems.

Options include 19″ rack cases, Zarges Mitraset Classic, Zarges Mitraset Racklite, DELTA® rack cases, SKB racks, Thermodyne Quadraflex and RackPack and modified racks.

Not every product needs to be housed in a rigid container. Bags, rolls, pouches and covers are practical alternatives.

Available as stand-alone items or for use within larger cases, we design and supply bags, rolls, pouches and straps to protect and retain your products, including bespoke inserts for added protection

Our industrial packaging solutions can be tailored to your sustainability goals.

The meticulous and detailed approach to the packaging designs we develop considers the full lifecycle of your product and its packaging – from storage to shipping and end-of-life.

the handling, storage and transport of your products

Where will the products travel to and what climatic conditions will they encounter? How will they be shipped? How will they be handled and stored? Is a closed-loop returnable solution required?

Getting to know your business, products and supply chain is the foundation of a stand-out industrial packaging design.

This will allow us to align our solutions with your protection requirements and objectives, like improving the sustainability of your industrial packaging.

the risk and protection requirements of your product

What is the size and weight of the product? What are its vulnerable points? What are the risks from impact shock, vibration, temperature extremes, humidity, electrostatic and magnetic devices and surface degradation? What is the best orientation within the pack?

Our experts will complete a 360-assessment of your product and any risks it may experience during its handling, storage and transit. They’ll pinpoint vulnerabilities, which will enable the most effective selection of industrial packaging materials and ergonomic design choices possible.

an effective industrial packaging design tailored to your needs

Based on our insights, a prototype pack is developed using SolidWorks design software.

Packaging materials are carefully selected and combined for maximum protection and cost-efficiency. Where possible, we will ensure the pack is eco-friendly.

The industrial packaging we create aims to:

the industrial packaging design rigorously in lab conditions

To ensure the industrial packaging solutions we’ve designed protect your products and meet your goals, we rigorously test them in controlled conditions

We can test packs to ISTA, ATA300, ETSI, BS1133 and Defence Standards.

This means you can be confident in the packaging designs we’re creating for you and enjoy peace of mind that your high-value products will be protected, no matter what conditions they’re subject to.

We work to rigorous certifications and standards to ensure our supply chain is ethical and minimises our impact on the environment.

Our manufacturing operations can also provide packaging made to specialist standards like ISTA, ATA300, ESTI and Defence Standards.

Our commitment to your business goes beyond design, manufacture and assembly.

The services we offer can be tailored to your needs too. They include:

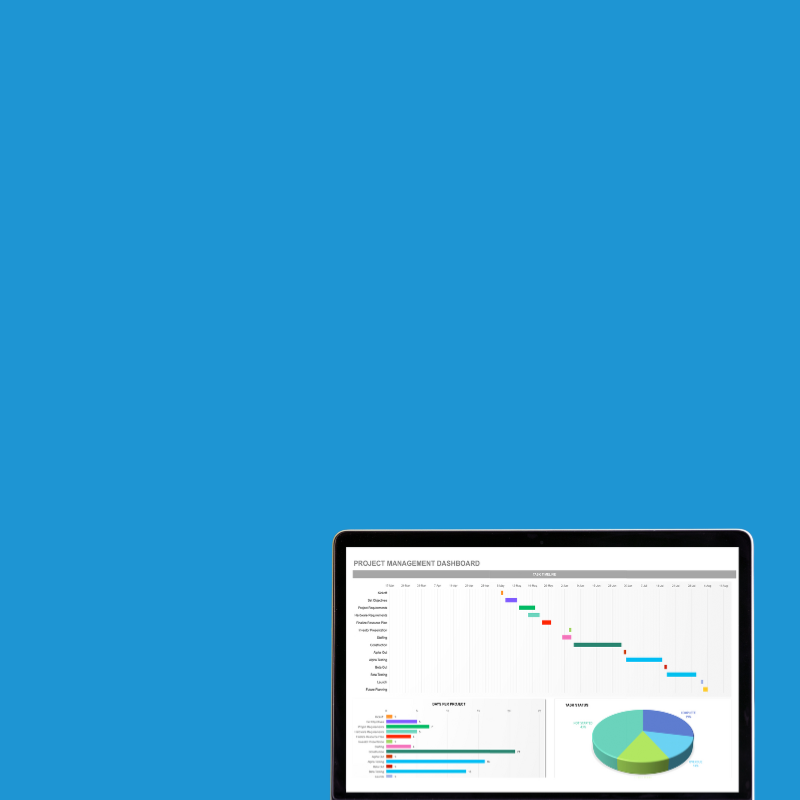

Did you know 90% of your packaging costs could be hiding behind the unit price you pay?

Our approach to creating industrial packaging design carefully considers not only your products and the materials used to make packaging, but key areas across your supply chain that can be influenced by packaging.

This means we can skillfully select designs and materials that produce packaging that is optimised for protection, saves you money and reduces your impact on the environment.

Through careful risk assessment and testing, we can develop lighter and smaller but stronger packs that protect your profits and your products, anywhere in the world.

We can reduce pack size and weight without compromising protection. So you get reduced load weights and fewer journeys, reducing supply chain costs and helping the environment.

Optimised packaging and packing processes can help you improve your supply chain productivity. We also offer a controlled packing service, on-site or off, to defence standards.

Our stock holding service means we can drip-feed packaging into your site. You get what you need, when you need it, without taking up valuable space in your warehouse.

Our experts will skillfully combine the right materials to create your packaging. So, you’ll use less material and improve sustainability while maintaining product protection.

Our packaging solutions will deliver undamaged products in packs that are easy to open, easy and safe to dispose of, or easy to return, boosting your customer satisfaction.

Our industrial and specialist packaging guide provides essential insights into different industrial packaging solutions, common materials used in their manufacture, and looks at good industrial packaging design.

Understand the often complex terminology used to describe industrial packaging designs, products and materials.

Learn about what makes a good industrial packaging design and design considerations for different sectors like aerospace, electronics, medical, and defence.

Explore key industrial packaging products from heavy-duty corrugated and Tri-Mite® through to timber cases, Correx® and anti-static packaging.

At Macfarlane Packaging, we manufacture industrial packaging from many materials. Some of the industrial packaging solutions we offer include:

These packaging products and materials are available through our specialist manufacturing division, who can guide you on the ideal packaging solution for your high-value products.

Specialist packaging from Macfarlane Packaging can be designed in a number of ways for a wide range of items. This includes anti-static and conductive packaging, corrugated coatings, VCI packaging, as well as inserts and fittings.

Anti-static and conductive packaging

Corrugated coatings

VCI Packaging

Cardboard dividers and fittings

Industrial packaging encompasses various materials such as corrugated cardboard, Correx®, moulded plastic, and timber crates, which are used for transporting and storing goods during manufacturing or within a supply chain. Unlike consumer or retail packaging, which serves both promotional and shipping purposes to end-users, industrial packaging focuses solely on facilitating transportation and storage within industrial settings or supply chains.

As the public is becoming increasingly aware of environmental issues, manufacturers are under growing pressure to adopt more sustainable practices. A …

Are you shipping fragile and sensitive electronics? Then you may be looking for packaging to protect your products during handling and transit. While …

Corrosion is the gradual deterioration of metals caused by the action of air, moisture or a chemical reaction (such as an acid) on their surface. On f…

You can have industrial packaging delivered to you from one of our regional distribution centres. UK delivery is available to and around the following locations:

Aberdeen, Aylesbury, Banbury, Barnsley, Bath, Bedford, Bicester, Birmingham , Bolton, Bradford, Bridgewater, Bridport, Bristol, Burton-upon-Trent , Cambridge, Chelmsford , Cheltenham, Chester , Chichester, Colchester Cornwall, Coventry, Crewe, Derby, Devon, Dewsbury, Dudley, Dundee, Durham, Edinburgh, Essex, Exeter, Fareham, Gateshead, Glasgow Glossop Gloucester, Grantham, Harlow, Heathrow, Hemel Hempstead, Hereford, High Wycombe, Horsham, Hull, Inverness, Isle of Wight, Kent, Kidderminster, Lancaster Leamington Spa, Leeds, Lincoln, Liverpool , London , Luton , Manchester, Middlesborough, Milton Keynes, Newbury, Newcastle-under-Lyme, Newcastle-upon-Tyne, Norfolk, North Wales , Northampton, Nottingham , Oldham, Oxford , Plymouth, Reading, Salisbury, Sheffield, Shrewsbury, Shrewsbury, Slough, Somerset , Somerton, South Shields, South Wales, Stafford, Stockport , Stoke-on-Trent , Stratford-Upon-Avon, Sudbury, Sunderland, Surrey, Sussex , Teesside, Telford, Uxbridge, Wakefield, Walsall, Warrington, Warwick , Watford, Wigan, Windsor, Wolverhampton, Worcester, Wrexham, Yeovil, York.

You can also have industrial packaging from Macfarlane Packaging delivered across Ireland and Continental Europe. Click to find your closest UK location or nearest Continental European site.